TCE625

Trusted Inconel625 protection for demanding industrial use

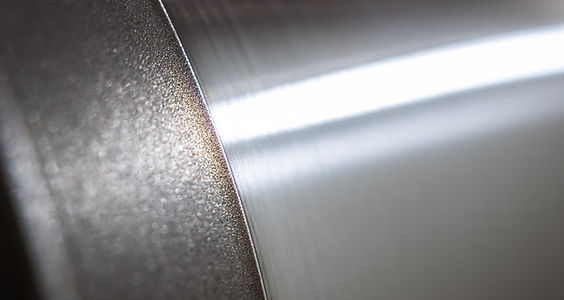

TCE625 is a premium laser clad layer based on Inconel 625 – one of the most established and trusted alloys in the laser cladding industry. Known for its exceptional corrosion resistance, solid wear protection and metallurgical bond to the base material, this coating won’t peel or delaminate. The result: components with a significantly longer service life and dependable performance in critical applications.

Extensively used in offshore, dredging and heavy industry

TCE625 is among the most widely applied laser‑clad coatings worldwide particularly valued in offshore environments and heavy‑duty industrial sectors. Its proven chemistry provides reliable protection against saltwater exposure, harsh weather and aggressive chemicals. While its toughness makes it suitable for equipment under constant mechanical stress. This combination of resilience and durability makes TCE625 the go‑to solution for extending the life of critical parts in the harshest operating conditions.

Benefits of TCE625

Inconel 625 laser cladding offers a range of key advantages, with its exceptional corrosion resistance standing out as the most important benefit for offshore and heavy‑duty applications.

Proven Industry Standard

TCE625 is one of the most widely applied Inconel 625 coatings in the world – trusted for decades in offshore, chemical, dredging and heavy‑duty industries.

Superior Corrosion Protection in Harsh Environments

Especially effective against seawater, chlorides and a wide range of chemicals making it a go‑to choice for offshore and marine equipment.

Versatile Application Range

From hydraulic rods, drums and rollers TCE625 performs consistently across many different components and base materials.

Thermal Stability

Maintains its protective qualities at both high and low operating temperatures, ideal for components exposed to fluctuating heat or cold.

Maintenance-Friendly Solution

Because it’s a well‑known and widely used coating, repairs, touch‑ups and inspections are straightforward – keeping downtime and costs predictable.

Specification

Value

Hardness (HV)

350 HV

Hardness (HRC)

35.5 HRC

Rockwell indentation

No cracking around indentation

Bonding strength

Infinite (metallurgic bonding)

Elasticity and Ductility

Excellent

Heat Affected Zone (HAZ)

<5% of layer thickness

++++ (4 of 5)

1.30 (25% increase)

52 volume loss/mm³

+++++ (5 of 5)

No corrosion after > 4200hr

< 0%

No visible corrosion

Layer cracks

No cracks

Wear score

ASTM-G65A

ASTM-G65B

Corrosion score

Saline droplet test

Porosity

Destructive porosity

Capacity

EHLA Laser Cladding

Ø1000 x 15.000mm

20.000kg